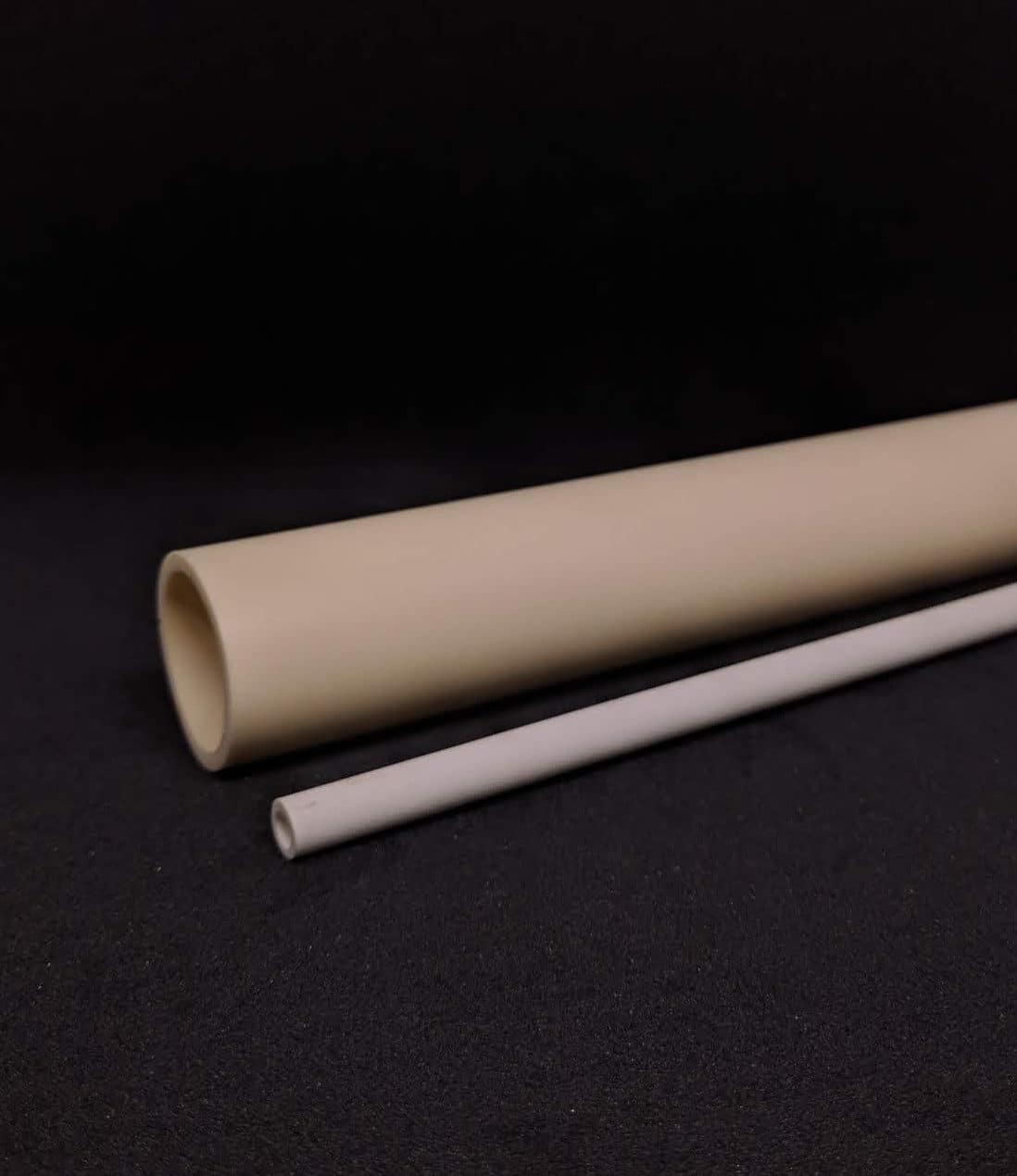

Antslab offers Ceramic Tube- Alumina Tubes with 99.5% Al2O3. Because high-temperature processes demand reliable components, our Alumina Tubes are most apt. Laboratory and industrial furnace applications up to 1700°C uses Alumina Tubes 99.5% and provide desired protection against the corrosive atmosphere. Likewise, it also protects the thermocouple sensors against mechanical damages.

Following are the properties of Alumina Tubes (Ceramic Tube)

- The high temperature is resistant.

- Thermal shock resistant.

- Corrosion resistant.

- High thermal conductivity.

Chemical Analysis of Alumina Tubes

| Constituents | Alumina 99.5% |

|---|---|

| Al2O3 Min | 99.5 |

| SiO2 Max | 0.2 |

| Fe2O3 Max | — |

| Na2O Max | 0.2 |

Physical Properties of Alumina Tubes

| Constituents | Alumina 99.5% |

|---|---|

| Colour | Ivory |

| Sp.Gr. – gms/cc | 3.9 |

| Water Absorption | 0 |

| Max Service Term | 1650 |

| Gas Permeability | Nil |

| Hardness R45N | 83 |

| Chemical Resistivity | Excellent |

| Flexural Strength N/mm2 | 365 |

| Tensile Strength N/mm2 | 260 |

| CTE (RT-14000 C) x 10-6 /°C Max. | 8.3 |

Finally, the values are obtained from standard bars & cubes, Data on other shapes shall differ, the data should not be taken as a specification but for general guidance only. Furthermore, shop a wide variety of Alumina Tubes- Ceramic Tube with 99.5% Al2O3 from antsLAB™. We offer both ends open type and One end closed type for application up to 1700C.

Reviews

There are no reviews yet.